T12 PLUS OSS YELLOW SERIES SOLDERING IRON

OSS TEAM

Model: T12 Plus

Material: flame retardant material

Color: yellow

voltage range

: AC100~240V

Peak power: 75W

Temperature range: 100~480°C

Temperature accuracy: ±5°C/40°F

Working conditions:: 10~50°C, humidity <80%

Heating method: intelligent PID control

Features: LCD display, adjustable sleep time, automatic sleep

6 seconds to melt tin and heat quickly

User’s manual

T12 series welding table instruction and operation

Automatic dormancy

Adjustable dormancy time

The temperature returns quickly

6 seconds to melt tin

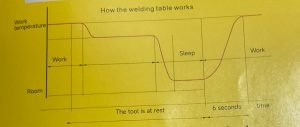

How the welding table works

Meets lead-free soldering standard

Anti-static “skin effect” protective shell

When the no-operation time reaches the set sleep time, the soldering station will. automatically enter the sleep mode. At this time, it is necessary to press any key of the host or pick up the handle to restore the working mode of the soldering station.

About the problem that the temperature jump of the new heating core prompts the error

The new heating core used for the first time needs to be aged before it can work stably (there are many domestic heating core manufacturers, the quality is uneven, and the aging time is also different, about 3 ~ 10 minutes). The temperature jump is large when it is just installed, and even the error is prompted, which belongs to the normal range. At this time, please adjust the temperature of the welding table to 350 °C and age for a period of time before it can be used normally. [OSS heating core does not need aging]

• This soldering station incorporates an automatic sleep function that extends the life of the tip by reducing the temperature of the tool when it is not in use.

It is 3-5 times longer than the traditional way, and it also saves electricity.

• When the no-operation time reaches the set sleep time, the soldering station will automatical enter the sean node restore the working mode of the sady ing

station.

• This ework efficiency.

| Model: | OSS T12 PLUS | Power: | 75W |

| Temp: | 100~480°C | Temp accuracy: | +5°C/40°F |

| Heating mode: | Intelligent PID

temperature control |

Automatic sleep: | YES |

| Voltage range: | AC100~240V,50/60Hz | Environmental requirement |

10~50°C; <80% RH |

1. Control panel description

II. Basic operations

- Normal use mode: In the power-on state, press the temperature plus or minus key todirectly adjust the temperature value (100-480 degrees Celsius).

- Function setting mode: In the power-on state, press the menu key for 1 second and then release it to enter the parameter setting function.

- Menu options: P- I,P -2,P – 3, click the menu key function options. Long press the menu key and it will automatically save and exit the setting interface.

When the no-operation time reaches the set sleep time, the soldering station will automatically enter the sleep mode. At this time, it is necessary to press any key of the host or pick up the handle to restore the working mode of the soldering station.

Ill. Parameter setting:

- The temperature can be increased or decreased through the temperature adjustment key. Click/one Press the temperature increase or decrease key to set the temperature;

- Press and hold the function menu button to enter/exit the setting page, and click to select the setting item:

P – 1: Sleep setting, adjust to OFF to turn off the sleep function; adjust 1-120 min, turn on the sleep function of delay time, if the handle does not move, wait for the corresponding time,

the wedelag station automatically enters sleep, cooling

without heating; exit the save setting.

P – 2: Set the sound switch, adjust it to OFF to turn off the prompt sound, and adjust it to ON to turn on the prompt sound; exit the save setting.

P – 3: Temperature error calibration setting, with a calibration range of + 50 °C. Make the soldering station work normally and heat it to the set temperature, correctly place the welderingzale at the temperature measuring position rature of the temperattric iron temperature measuring instrument, read the temperature of the temperature measuring instrument and the set temperature of the soldering station, if the temperature of the temperature measuring instrument is greater than the set temperature of the soldering station,

take the positive error value, operate the

increase/decrease key to adjust the calibration value of the soldering station to the current positive error value; exit and save the setting. If the temperature of the thermometer is less than the set temperature of the soldering station, take the negative error value, and operate the increase/decrease button to adjust the calibration value of the soldering station to the current negative error value; exit and save the setting.

IV. Error code:

5-E: The welding station is not connected to the handle/heating core correctly;

Solution: Connect the handle/heating core correctly.

OCP: Heating core short circuit/heating core mismatch error; solution: remove the heating core, check whether the heating core is short circuit, if so, replace the heating core.

OPP: The welding station is abnormally heated and an error is reported: solution: remove the heating core and reinsert the heating core.

Notes:

1 horder lo extend the service life of the soldering tip, please do not adjust the temperature in to high for a long time. Generally, 350 degrees is the most suitable temperature for welding.

2 please do a good job in the maintenance of soldering tip, keep the tip clean and solder maintenance, prevent tip oxidation.

Replace the soldering tips, especially from different manufacturers, please select the coresponding model and recalibrate the temperature.

the new soldering iron head, especially domestic head, need to go through aging to work stable, just inserted the temperature jump is large, even the error is normal. Please dispatch the temperature to 350 °C

about aging to use for a period of time.

Site welding table reports the error “5-E, “OCP” or “OPP”, check that the plug and welding head of the handle are inserted properly and that the handle and welding head are not damaged.

§ When doing important welding work, please ensure that your power socket is connected to the ground. If necessary, please connect the independent ground connector at the end al the welding table to the ground reliably through the wire.

7. Do not try to insert the handle of other manufacturers into the soldering console.

The incompatible handle may cause vibration and wake up failure, hardware damage, soldering tip temperature loss, fire and other serious consequences.

There are no reviews yet.